The convergence of IT and OT in the context of Industry 4.0 has led to a crowded market of security solutions targeting the shop floor on different levels. While the security of the legacy IT systems was part of the initial planning of those systems, the industry now faces the challenge to integrate security solutions in legacy OT systems.

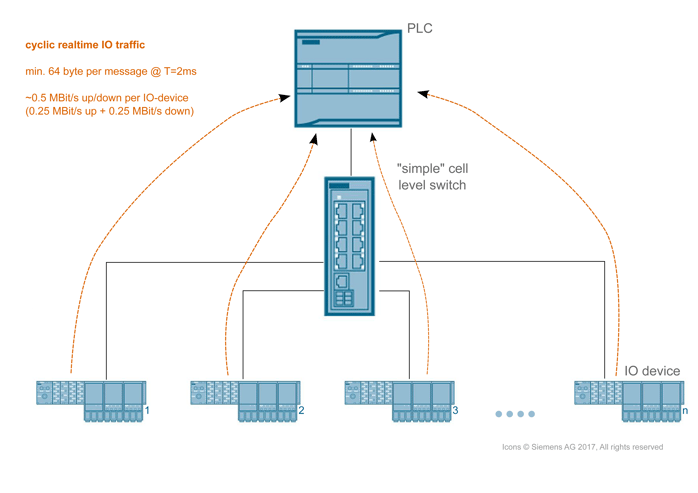

Figure 1: Layers of a typical automation system using Profinet

At least for the lower levels of the Industry 4.0 infrastructure, (control and device level) security solution vendors tend to use the mirror/span ports offered by the network switches to integrate their solutions into the infrastructure.

Here I will explore why those mirror ports shouldn't be used to build security solutions. Based on the hardware commonly used in Industrial Networks, we will specifically look at:

I came across some research data Garland posted from Packet Pioneer that said a mirror port will drop up to 8% of the frames.

I took a deep breath because an 8% loss is a lot, especially if you are going to build security applications on top of the mirrored network traffic from systems using Profinet in different flavors (configuration, real-time and alarm IO).

I continued reading and calmed down, in their research, they used iperf to saturate a link that was mirrored at the same time. Saturation means the system is in an overload condition, so drops are acceptable. And every network engineer will agree, that using more than 80% of the bandwidth of an Ethernet link will result in weird behavior at some point.

But I couldn’t get past these questions, ‘What happens, if only small frames are transmitted?’ The average frame size in industrial networks is ~130 bytes, (calculated from a sampling of shop floor traces containing mostly Profinet) but the aforementioned test was done using 1500 byte frames (iperf usually uses TCP and that will send the data in chunks of MTU size). ‘What if we use more than one link?’ On the process level usually one controller talks to a number of IO-devices via one switch.

Figure 2: Process level - Profinet master and IO-Devices

In the context of industrial automation systems a test setup using a one-to-one connection running 1500 byte frames does not reflect a common scenario. And regarding automation systems, what if the traffic on those multiple links shows different bandwidth patterns?

Keeping those questions in mind I built a small test setup based on the open source network traffic generator and analyzer Ostinato. This tool offers a nice interface to create well defined streams of Ethernet frames for multiple network interfaces while intercepting traffic at the same time.

This is not a hardware frame generator, but capable of handling multiple 100 Mbps streams with relative low-tech network interface cards. 100 Mbps is absolutely sufficient for running tests against network switches commonly used on the lower levels in a shop floor automation environment, as this is the usual network speed used there.

Want to see the test details and results? Read Thomas' tech note on Full Duplex Capture in Industrial Networks to learn the best practices for using network TAPs in Industry 4.0 security applications.

If the inline security tool goes off-line, the TAP will bypass the tool and automatically keep the link flowing. The Bypass TAP does this by sending heartbeat packets to the inline security tool. As long as the inline security tool is on-line, the heartbeat packets will be returned to the TAP, and the link traffic will continue to flow through the inline security tool.

If the heartbeat packets are not returned to the TAP (indicating that the inline security tool has gone off-line), the TAP will automatically 'bypass' the inline security tool and keep the link traffic flowing. The TAP also removes the heartbeat packets before sending the network traffic back onto the critical link.

While the TAP is in bypass mode, it continues to send heartbeat packets out to the inline security tool so that once the tool is back on-line, it will begin returning the heartbeat packets back to the TAP indicating that the tool is ready to go back to work. The TAP will then direct the network traffic back through the inline security tool along with the heartbeat packets placing the tool back inline.

Some of you may have noticed a flaw in the logic behind this solution! You say, “What if the TAP should fail because it is also in-line? Then the link will also fail!” The TAP would now be considered a point of failure. That is a good catch – but in our blog on Bypass vs. Failsafe, I explained that if a TAP were to fail or lose power, it must provide failsafe protection to the link it is attached to. So our network TAP will go into Failsafe mode keeping the link flowing.

Single point of failure: a risk to an IT network if one part of the system brings down a larger part of the entire system.

Heartbeat packet: a soft detection technology that monitors the health of inline appliances. Read the heartbeat packet blog here.

Critical link: the connection between two or more network devices or appliances that if the connection fails then the network is disrupted.